Single Edge Safety Razors:

Feature a single cutting edge with a protective guard.

Known for their simplicity and ease of use.

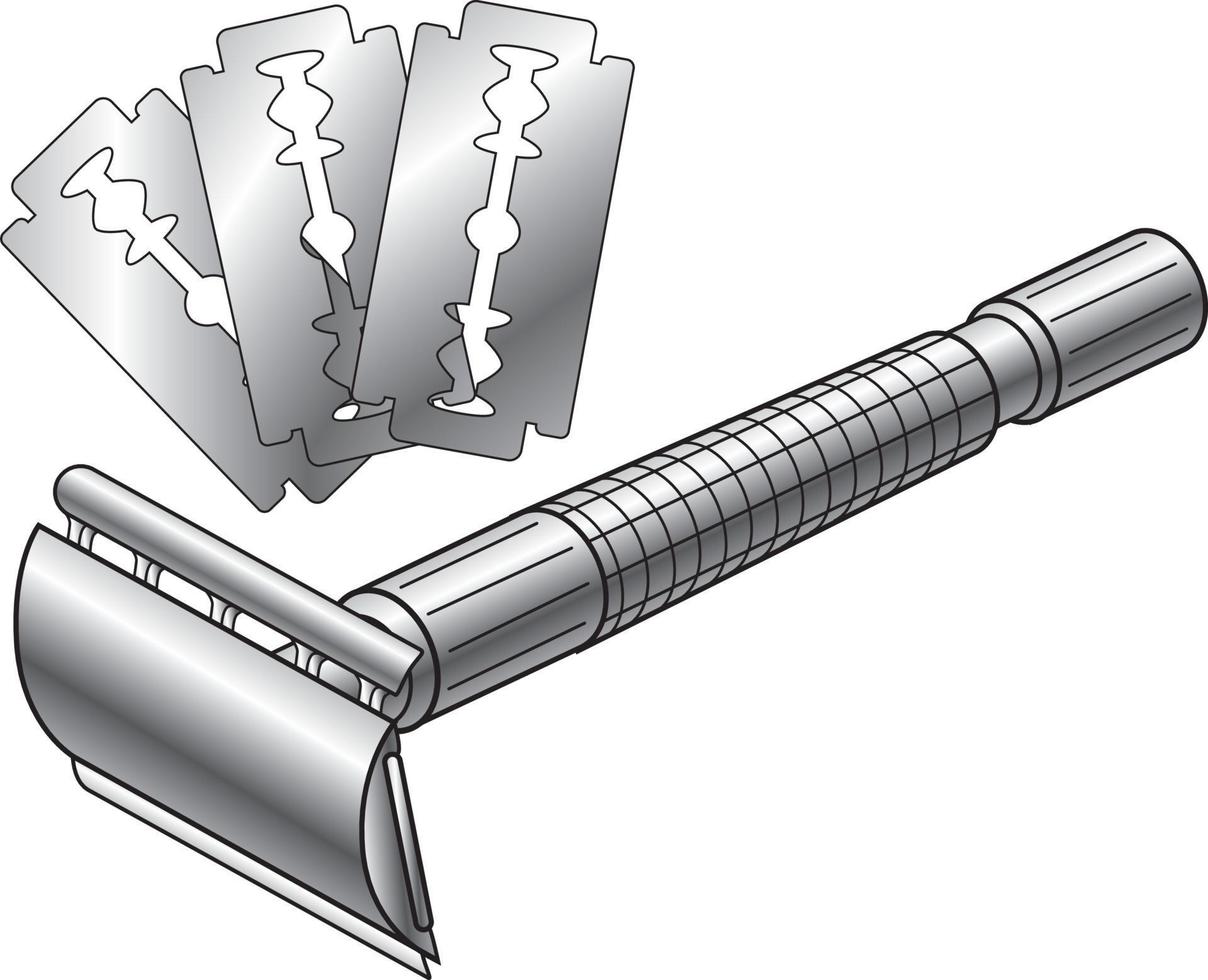

Double Edge Safety Razors:

Have two cutting edges on opposite sides of a single blade.

Provide a close shave with added safety features.

How to Make Safety Razors

Designing: Develop ergonomic handles and precise blade angles for effective shaving.

Material Selection:

Blades: High-quality stainless steel for sharpness and durability.

Handles: Lightweight metals like stainless steel or aluminum, or durable plastics for comfort and grip.

Safety Features: Design protective guards and proper blade exposure for safe shaving.

Manufacturing Process:

Blade Production: Precision grinding and honing of stainless steel blades.

Handle Manufacturing: Injection molding or machining of ergonomic handles.

Assembly: Expert assembly of blades and handles with rigorous quality control checks.

Quality Control: Testing for blade sharpness, handle durability, and overall safety standards.

Personality Development Through Safety Razors

Customization: Offer personalized handle designs, colors, or materials to suit user preferences.

User Experience: Focus on providing a smooth, irritation-free shave with control over shaving angle and pressure.

Care for Safety Razors

Cleaning: Rinse razor head thoroughly after each use to remove hair and shaving cream residue.

Blade Maintenance: Replace blades regularly to ensure sharpness and hygiene.

Storage: Store razors in a dry area to prevent rust and damage to blades or handles.

Good Sides of Safety Razors

Close Shave: Provide a close shave with reduced risk of irritation compared to multi-blade razors.

Economic: Long-term cost savings as replacement blades are often inexpensive.

Environmentally Friendly: Minimal plastic waste compared to disposable razors.

Bad Sides of Safety Razors

Learning Curve: Requires practice to master the shaving technique, especially for beginners.

Safety Concerns: Improper use can lead to nicks or cuts, though less common with proper technique.

Replacement Blades: Regularly changing blades may require more effort compared to disposable razors.

Material Selection for Safety Razors

Blades: Stainless steel for sharpness and durability.

Handles: Stainless steel, aluminum, or durable plastics for ergonomic designs and comfort.

Grip Components: Rubber or textured materials for secure handling, especially in wet conditions.

Fashion and Design Trends

Ergonomic Designs: Sleek, modern handles with ergonomic grips for comfortable shaving.

Customization Options: Personalized color choices or handle designs to appeal to different preferences.

Vintage Revival: Growing interest in classic designs and materials for a nostalgic shaving experience.

Market Trends

Environmental Consciousness: Increasing demand for sustainable shaving alternatives.

Quality and Craftsmanship: Appreciation for well-crafted, durable razors that offer long-term value.

Male Grooming: Rising interest in traditional grooming tools and techniques among men.

Customer Preferences

Shaving Performance: Priority on razors that deliver a smooth, close shave with minimal irritation.

Durability: Long-lasting blades and handles that withstand regular use.

Affordability: Value for money concerning initial purchase and ongoing maintenance costs.

Brand Reputation: Preference for trusted brands known for quality and reliability in shaving products.

Understanding these detailed aspects of safety razors can help manufacturers, designers, and retailers cater to market demands and customer preferences effectively.